News

Common Defects in Investment Casting

Some common defects that can occur in investment casting include: Shrinkage: When the metal solidifies, it can shrink and cause voids or cavities in the investment casting. Porosity: This is the presence of small voids or bubbles in the investment casting, which can weaken the structur......

Read MoreFactors Affecting Surface Finish of Iron Casting Prats

There are several factors that can affect the surface finish of iron casting parts: Mold Quality: The quality of the mold used for casting plays a significant role in the surface finish of the final part. A smooth and well-constructed mold will result in a smoother surface finish on the casti......

Read MoreAdvantages and Disadvantages of Investment Casting

Investment casting, also known as lost wax casting, is a manufacturing process that involves creating molds from wax patterns, then pouring molten metal into the molds to create complex and intricate parts. Here are some advantages and disadvantages of investment casting

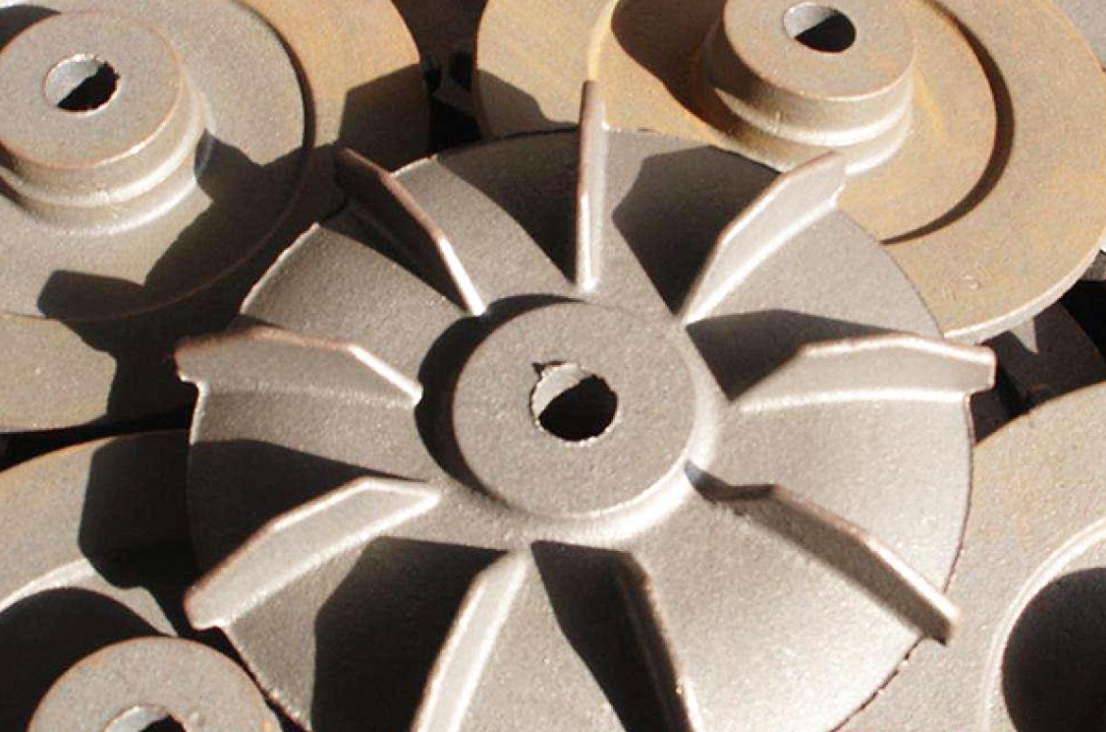

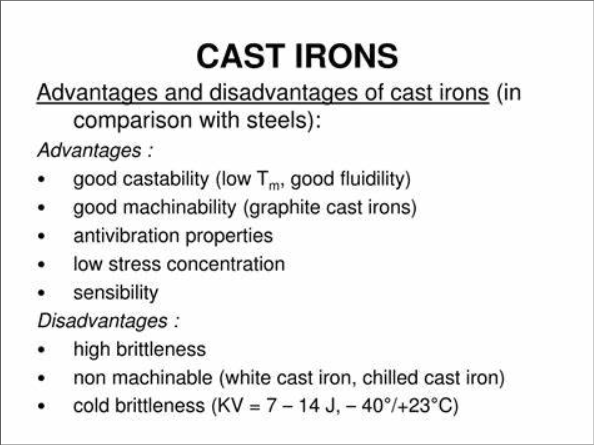

Read MoreAdvantages and Disadvantages of Iron Casting

Versatility: Iron casting can be used to create complex shapes and designs, making it a versatile option for a wide range of applications. Strength: Iron is a strong and durable material, making iron castings ideal for applications where strength and durability are important.

Read MoreWhat Is Stainless Steel Motorcycle Engine Cylinder Block

A stainless steel motorcycle engine cylinder block is a vital component of the engine that houses the cylinders where the combustion process takes place. It is made from stainless steel, a durable and corrosion-resistant metal known for its strength and heat resistance.

Read More