Industry News

Advantages and Disadvantages of Investment Casting

Investment casting, also known as lost wax casting, is a manufacturing process that involves creating molds from wax patterns, then pouring molten metal into the molds to create complex and intricate parts. Here are some advantages and disadvantages of investment casting

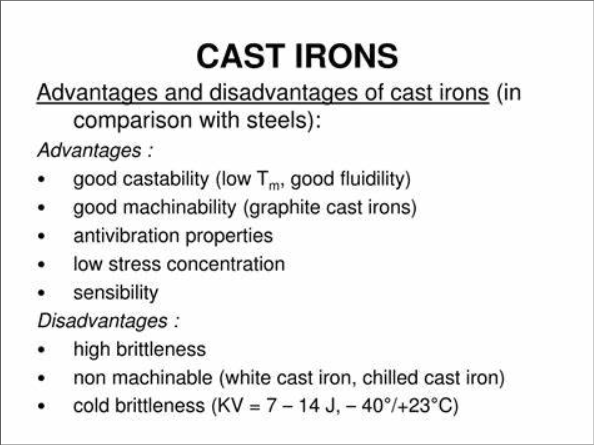

Read MoreAdvantages and Disadvantages of Iron Casting

Versatility: Iron casting can be used to create complex shapes and designs, making it a versatile option for a wide range of applications. Strength: Iron is a strong and durable material, making iron castings ideal for applications where strength and durability are important.

Read MoreWhat Is Stainless Steel Motorcycle Engine Cylinder Block

A stainless steel motorcycle engine cylinder block is a vital component of the engine that houses the cylinders where the combustion process takes place. It is made from stainless steel, a durable and corrosion-resistant metal known for its strength and heat resistance.

Read MoreProduction Process of Ductile Iron Castings

Melting: The process starts with melting scrap iron, steel, and other additives in a furnace at very high temperatures. The molten metal is then treated with magnesium to promote the formation of graphite nodules in the iron, giving it ductile properties.

Read MoreWhat Is Unbonded Post Tensioning System

An unbonded post-tensioning system is a method of reinforcing concrete structures using high-strength steel tendons that are grouted or filled with grease and covered in a plastic sheath before being tensioned. Unlike bonded post-tensioning, where the tendons are bonded to the concrete with grout,......

Read More