Industry News

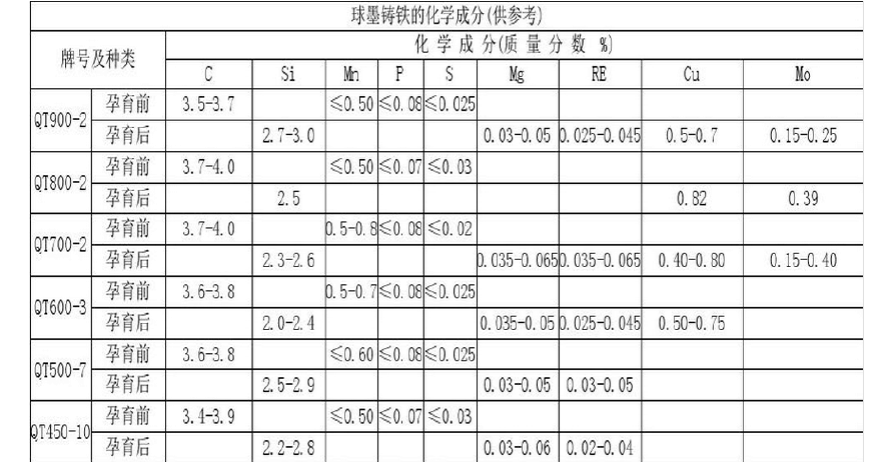

Nodularity in Ductile Iron Casting

Ductile iron casting is a widely used manufacturing process in various industries due to its excellent mechanical properties and cost-effectiveness. One of the critical factors that determine the quality of ductile iron castings is nodularity. In this article, we will explore the concept of nodulari......

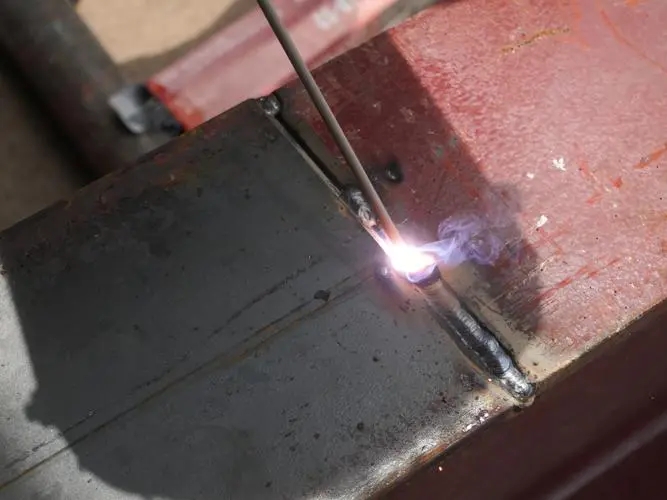

Read MoreWelding of Iron Casting Part

Iron casting parts are widely used in various industries due to their high strength and durability. However, in some cases, these parts may require welding to join them together or repair any defects. This article will discuss the process of welding iron casting parts, including the necessary equipm......

Read MoreWhat Is Iron Casting Shrinkage and Porosity

Iron casting is a widely used manufacturing process in which molten iron is poured into a mold to create a desired shape. However, during the solidification process, iron casting can experience shrinkage and porosity, which can affect the quality and integrity of the final product.

Read MoreHow to Deal with Iron Casting Surface Defects

Iron casting is a widely used manufacturing process in various industries. However, like any other manufacturing process, it is not without its challenges. One common issue that arises during iron casting is surface defects. These defects can affect the quality and functionality of the final product......

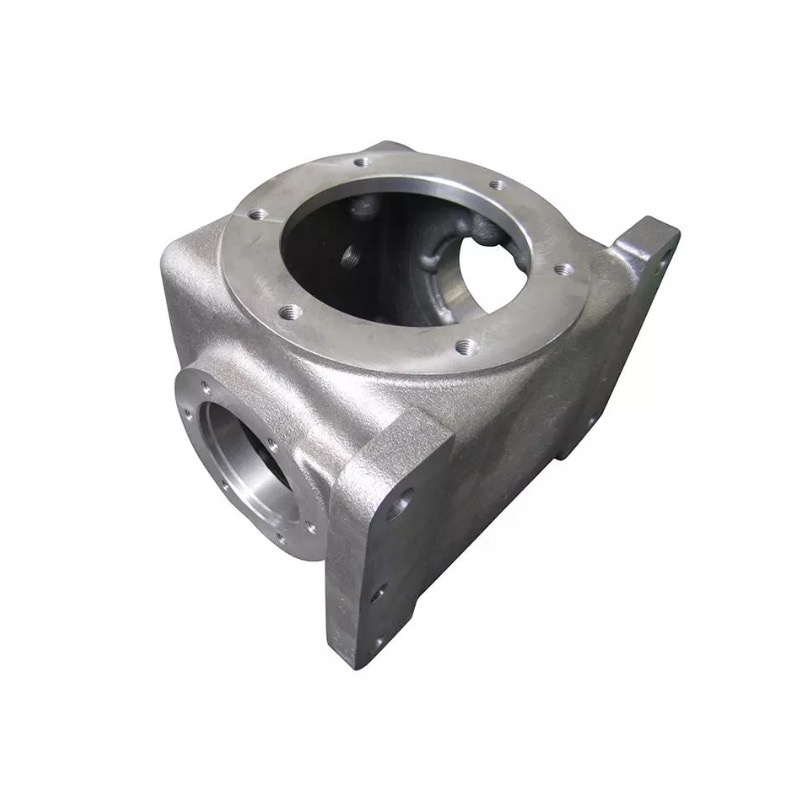

Read MorePerformance specifications for agricultural machinery castings?

Agricultural machinery castings are metal shaped objects obtained through various casting methods, that is, molten liquid metal is injected into a pre prepared mold through pouring, injection, suction, or other casting methods. The product is then cooled early and polished by subsequent processing m......

Read More