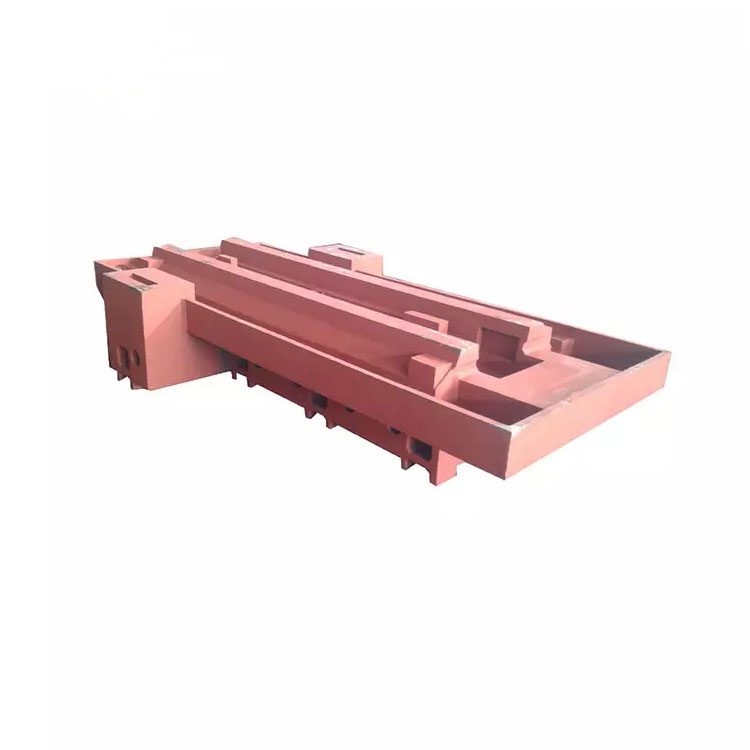

Cast Iron Machine Tool Bed Lathe Bed

Ningbo Supreme Machinery Co., Ltd is a professional gray iron and ductile Iron casting manufacturer and supplier in China. The main products include Cast Iron Machine Tool Bed Lathe Bed, motor casing, reducer shell, belt pulley, cast iron cradle, iron support, brake drum, axle support.

Send Inquiry

Cast Iron Machine Tool Bed Lathe Bed China advanced manufacturer and supplier - Ningbo Supreme Machinery Co., Ltd. Cast Iron Machine Tool Bed Lathe Bed is also be called heavy castings, the material is HT200-300, it’s divided into wooden mold casting and lost foam form casting. The machine tool castings’ production is that the metal mixture is heated to melt, so that it has the fluidity, and then poured into the mold cavity with a certain shape, under gravity or external force (Pressure, centrifugal force, electromagnetic force etc.) the mold cavity is full filled by the liquid, form the machine tool casting (parts) after the liquid is cooled and solidified.

Milling machine tool bed casting using advanced manufacturing technology, machine performance, reliable structure, simple operation, convenient maintenance, widely used in mechanical processing industry of heavy-duty, non-ferrous metal plane, the inclined plane and concave convex milling, has good performance to price ratio.

Features of Cast Iron Machine Tool Bed Lathe Bed

1. Adjustable angle head, able to mill bevel face.

2. Universal lathe, with Drilling Boring feature.

3. Worktable and Head are controlled by Panel, Operates simply.

4. Increased weight of Vertical Post, makes Better Process Stability.

5. High accuracy, error within 0.05mm.

6. Adopt Double tempering Cast, no deformation.

7. Hand scraping, More smooth worktable and lathe Body.

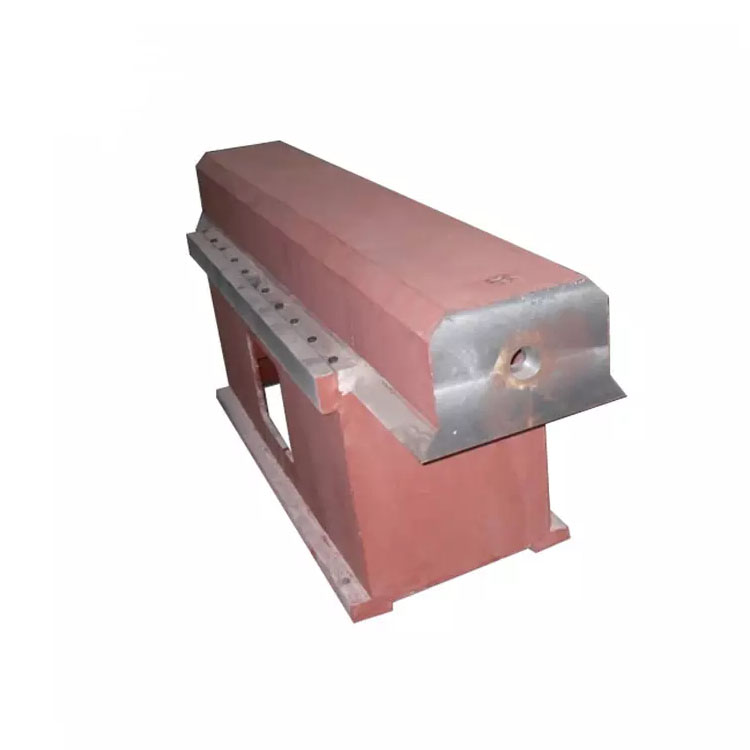

Basic Information for Cast Iron Machine Tool Bed Lathe Bed

Material: HT200-300

Specification: 1500-4000mm

Hardness of the working surface: HB160-240

Production process: sand casting or centrifugal castings

Molding type: resin sand molding

Surface coating: pickling oil and plastic-lined or covered with anti-corrosion paint

Working temperature: (20±5)℃

Precision grade: 1-3

Packaging: Pallet or Customized

|

Process |

resin sand casting |

|

Specification |

1. Material: gray iron HT200-300 2. Standard: ASTM 3. Surface finish: shot blasting, painting, machining,etc. 4. Weight: 100~40000kgs 5. Maximum Size: 10000x8000x5000mm |

|

Production facilities |

1. Casting facility: resin sand production line, Electric furnace, heat treatment furnace, shot blasting room 2. Machining facility: CNC, boring machine, milling machine, lathe, etc. |

|

Application |

Machine tool body |

|

Quality Inspection |

spectrometer, tensile test machine, hardness test machine, metallographic microscope. |

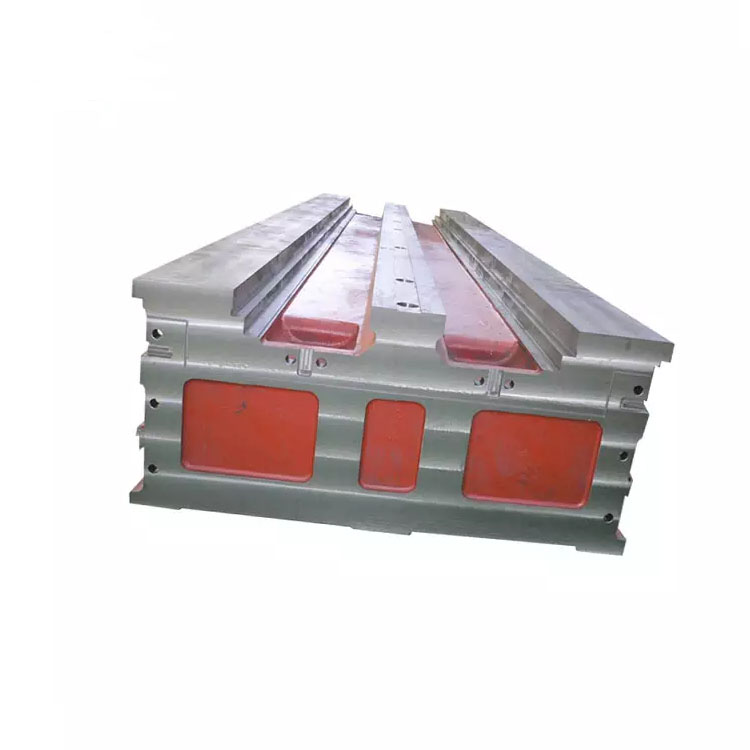

Production Process

We have updated our production line for making Cast Iron Machine Tool Bed Lathe Bed

Our production process include resin sand molding line, shell molding line, green sand casting and lost wax investment casting production process.

Machining Workshop

We have full set line of machining facilities, various CNC equipment and Machining Center can meet customers’ requirements. After machining, the casting parts will be completed. Then, they will be inspected and packed for delivery and shipment.

Quality Control

Checking the raw material after they reach our factory------- Incoming quality control

Checking the details before the production line operated

Have full inspection and routing inspection during mass production---In process quality control

Checking the goods after they are finished---- Final quality control

Checking the goods after they are finished-----Outgoing quality control

Packing and Delivery

Packaging of Cast Iron Machine Tool Bed Lathe Bed can be customized based on customer requirements to meet the different needs, such as plastic bag, carton box, wooden case, crate, etc.