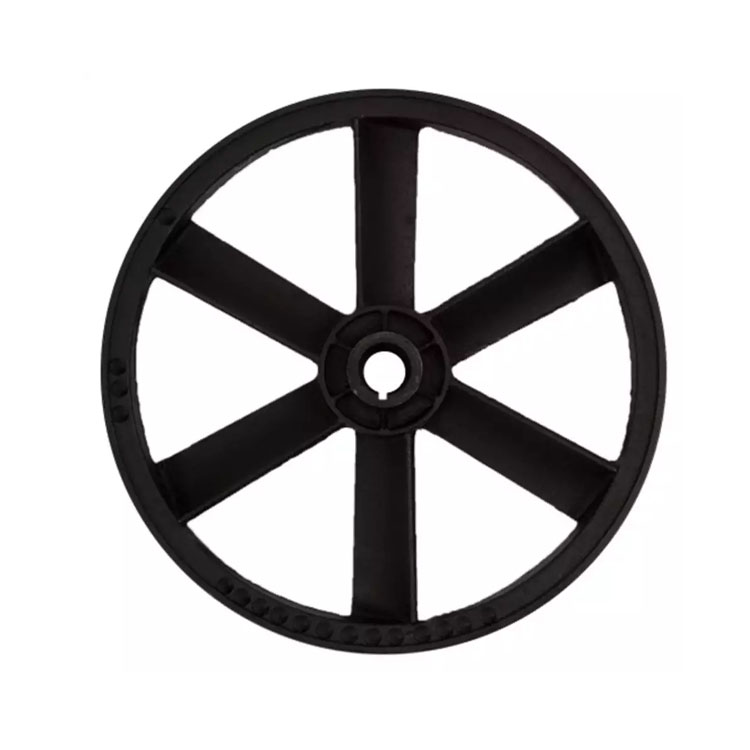

Cast Iron Flywheel

Ningbo Supreme Machinery is Manufacturer and supplier of high quality iron casting part in China. Products mainly include Cast iron flywheel, triangle pulley, diesel generator, diesel engine, pump set, flat pulley, cast iron flange. Products can be customized according to the drawings or samples provided by the customer.

Send Inquiry

As a professional China Cast Iron Flywheel manufacturers and suppliers, we provide customers with comprehensive project management services. Ningbo Supreme Machinery use green sand casting, resin sand casting or lost foam casting process to produce many kinds of cast iron fly wheel from 4” to 50”.

These cast iron flywheels are used for transportation, automotive and so on. The material of these cast iron wheels can be grey cast iron or ductile cast iron according to customers' requirement.

This wheel is meant for the roughest of applications on the poorest of floors.

Cast Iron Flywheel Features

1. Casted V belt pulley

2. Made in kinds gray iron material

3. In different V groove

4. Different Standard type or specially designed for buyer , pilot bore

5.Groove from 1 to 5

6. Material: gray iron GG 25 ( HT250), nodular cast iron GG 40 and so on

7. Surface treatment : blacken oxide, phosphating, painted, zink plated and so on

8. Quality:100% inspection before shipment.

|

1 |

Flywheel Grey iron casting sand casting cast iron OEM China foundry |

|

2 |

Material:grey iron, ductile iron |

|

3 |

Price:Because different material,process,instructure,machining requirements and surface treatment requirements will have different production cost. We will quote the exact price after studying the drawings. |

|

4 |

Process :precoated sand casting /shell mold casting/green sand/resin sand/lose foam casting,etc. |

|

5 |

Surface:E-coated,phosphated ,zinc plated ,painting etc. or as required. |

|

6 |

Quality Assurance: |

|

|

1) Visual inspection of surface. Porosities and blisters are not allowed. 2) Dimensional test acc. to production drawing. 3) Chemical analyses. 4) Mechanical properties in cast on test bar. |

|

7 |

Certification:ISO9001:2008 and TS16949. |

|

8 |

Packing:VCI antirust bag and pack with plywood case,exempt fumigation or as you required. |

Production Process

We have updated our production line for making Cast Iron Flywheel

Our production process include resin sand molding line, shell molding line, green sand casting and lost wax investment casting production process.

Machining Workshop

We have full set line of machining facilities, various CNC equipment and Machining Center can meet customers’ requirements. After machining, the casting parts will be completed. Then, they will be inspected and packed for delivery and shipment.

Quality Control

Checking the raw material after they reach our factory------- Incoming quality control

Checking the details before the production line operated

Have full inspection and routing inspection during mass production---In process quality control

Checking the goods after they are finished---- Final quality control

Checking the goods after they are finished-----Outgoing quality control

Packing and Delivery

Packaging of Cast Iron Flywheel can be customized based on customer requirements to meet the different needs, such as plastic bag, carton box, wooden case, crate, etc.