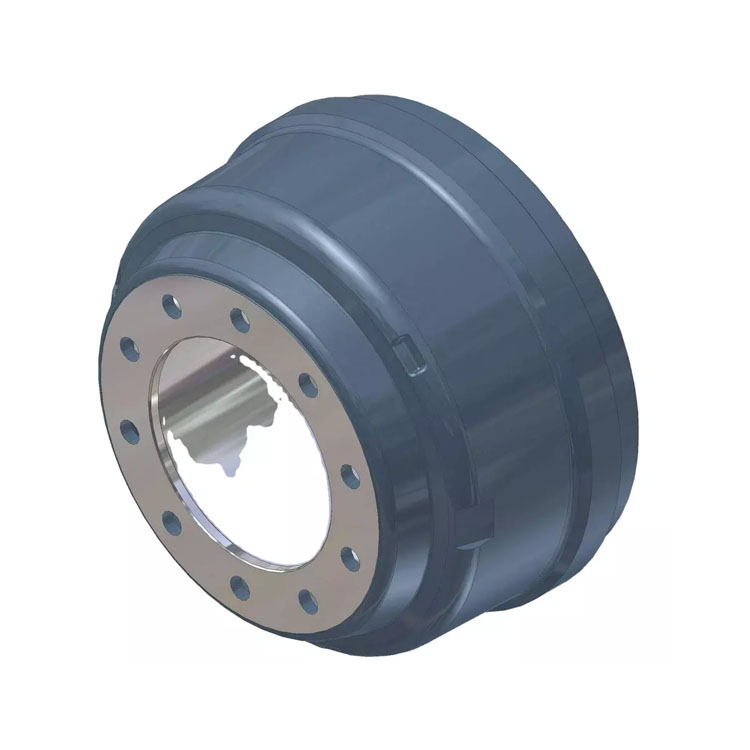

Cast Iron Brake Drum

Ningbo Supreme Machinery is Manufacturer and supplier of high quality Cast Iron Brake Drum. We specialize in production of cast iron Braking drum (Brake hub) for all kinds of automobile & trailer& tractors. We have completed production line and have advanced equipment for Casting, Machining and quality testing.

Send Inquiry

Ningbo Supreme Machinery is Manufacturer and supplier of high quality Cast Iron Brake Drum. Products are mainly exported to America, German, Japan, Korea, Poland and Italy etc. Welcome to contact with us for cooperation.

Cast iron brake drum is shaped like a tambourine in the cast iron pieces, with the tire fixed and the same rotation speed. Promote the use of hydraulic brake shoes contacts the inner drum brakes, the friction generated by exposure to suppress the rotating tire to achieve the purpose of the brakes.

Material:The material degree for brake drums is gray iron class 35 (HT250, FC250, GG25, ISO300, G250.

Production Process: Resin Sand Casting.

Related Product:brake wheel cylinder, brake shoe and other relevant connecting rod, spring, shoot nails.

Product Details

|

Working life |

Long life time, above 60000-80000kms |

|

Application |

Auto brake system |

|

Material: |

Gray iron HT250 |

|

Weight |

20kgs-85kgs |

|

Chemical composition |

C:3.0-3.3% Si:1.6-1.9% Mn:0.7-0.9% P:<0.12% S<0.12% |

|

Quality: |

Meet or Exceed OE Manufacturer Specifications; Stable friction, Deliver High Stopping Power, Reliability And Safety. Optimize The Performance Of Vehicle's Braking System. |

|

Certification |

ISO/TS16949 |

|

Package |

1.PP bag+individual box+outer carton+pallet; |

|

2.According to buyers' requirements. |

|

|

OEM/ODM |

Both |

|

Port |

Ningbo |

|

QC |

1. Sample check; |

|

2. Before production, mould and model check; |

|

|

3. Technicians self check in production; |

|

|

4. Engineer spot check; |

|

|

5. Packing check; |

|

|

6. Check before shipping. |

Production Process

We have updated our production line for making Cast Iron brake drum.

Our production process include resin sand molding line, shell molding line, green sand casting and lost wax investment casting production process.

Machining Workshop

We have full set line of machining facilities, various CNC equipment and Machining Center can meet customers’ requirements. After machining, the casting parts will be completed. Then, they will be inspected and packed for delivery and shipment.

Quality Control

Checking the raw material after they reach our factory------- Incoming quality control

Checking the details before the production line operated

Have full inspection and routing inspection during mass production---In process quality control

Checking the goods after they are finished---- Final quality control

Checking the goods after they are finished-----Outgoing quality control

Packing and Delivery

Packaging of Cast Iron brake drum can be customized based on customer requirements to meet the different needs, such as plastic bag, carton box, wooden case, crate, etc.