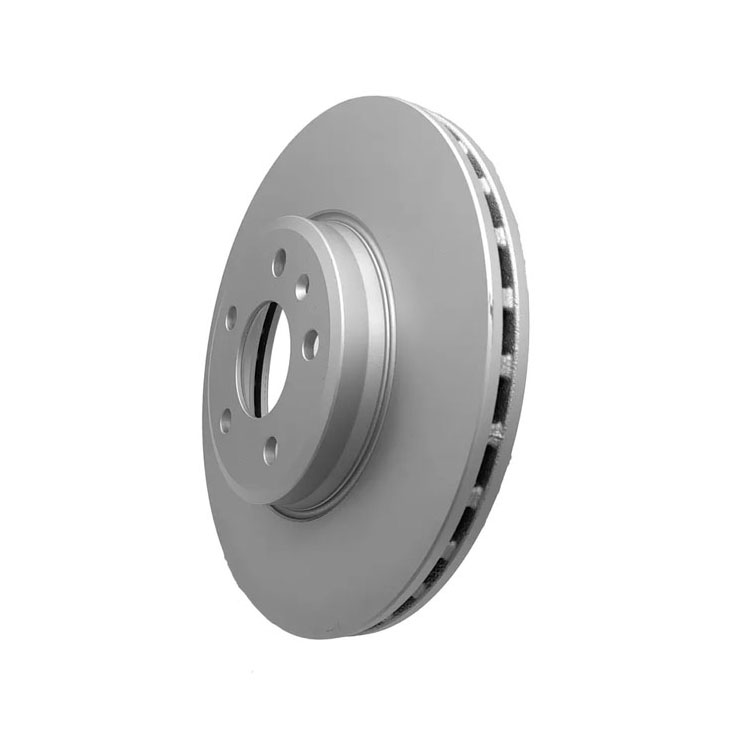

Cast Iron Brake Disc

We are professional manufacturer and supplier for cast iron brake disc in China, our products has already widely used in trucks ,cars. etc. Our factories have professional production equipment & assembly line and advanced assembly testing facility for Auto Brake System. Our main markets are Europe , Americas and the Middle East.

Send Inquiry

We are professional manufacturer and supplier for cast iron brake disc in China, Truck Braking System Parts:brake disc , brake pads,brake drums etc.

Truck Cooling System Parts:Radiator, intercooler,oil cooler, condenser,heater,expansion tank,water pump,belt tensioner etc.

Truck Steering System parts:Steering pump

Truck Wheel System Parts:wheel hub bearing,wheel rim etc

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Cast Iron Brake Disc Features

1. Rust-preventative coating;

2. Mill-balanced for proper rotor function;

3. Brake disc quality validated for proper metallurgy and correct brake plate thickness;

4. Non-directional brake surface finish for consistent braking;

5. Chamfer angle follows the OE design;

6. 12-month/12,000 mile warranty.

7. Wide range models brake disc for the vehicles in world market, with high quality gurantee.

8. Material: HT250, grey cast iron, with long working life.

Product Information

Cast iron Brake disc and brake rotors can be made from many different materials. Each material has its own effect on the performance of the rotor. Some brake rotors use different design methods, such as piercing the rotor in different patterns, for high-performance upgrades to vehicle braking systems. The ideal brake rotor is usable in any weather, no matter if it is rainy or sunny. It also has the capability to easily and quickly dissipate heat from the friction of the pads rubbing against its surface.

|

Item Name |

cast iron brake disc |

|

Casting Type |

Gray Iron Casting |

|

Production Process |

Sand Casting / Clay Sand Casting / Green Sand Casting/ Resin Sand Casting |

|

Casting Manufacturer |

Supreme Machinery Co.,Ltd |

|

Quality Control |

Spectrum Analyzer, Three-Coordinate Detector, Metallographic Analyzer, Tensile Testing Machinery |

|

Standards |

ASTM A48, ISO 185, DIN 1691, EN 1561, JIS G5501, UNI 5007, NF A32-101, BS 1452, IS 210, |

|

Material Grade |

HT250 |

|

Application |

Trucks and Cars |

|

Machining Tolerance |

0.01-0.05 |

|

Inspection Method |

visual, dimensional, X-ray inspection |

Grey Iron Casting Material Comparison Table:

|

Cast iron with lamellar graphite DIN EN 1561 |

Germany DIN 1691 |

France NF |

Great Britain BS |

Netherlands NEN |

Sweden MNC |

USA ASTM A48 |

|

EN-GJL-150 |

GG-15 |

Ft 15 D |

Grade 150 |

GG 15 |

01 15-00 |

20 B / 25 B |

|

EN-GJL-200 |

GG-20 |

Ft 20 D |

Grade 180/220 |

GG 20 |

01 20-00 |

25 B / 30 B |

|

EN-GJL-250 |

GG-25 |

Ft 25 D |

Grade 220/260 |

GG 25 |

01 25-00 |

35 B / 40 B |

|

EN-GJL-300 |

GG 30 |

Ft 30 D |

Grade 300 |

GG 30 |

01 30-00 |

40B / 45 B |

Production Process

We have updated our production line for making Cast Iron brake disc.

Our production process include resin sand molding line, shell molding line, green sand casting and lost wax investment casting production process.

Machining Workshop

We have full set line of machining facilities, various CNC equipment and Machining Center can meet customers’ requirements. After machining, the casting parts will be completed. Then, they will be inspected and packed for delivery and shipment.

Quality Control

Checking the raw material after they reach our factory------- Incoming quality control

Checking the details before the production line operated

Have full inspection and routing inspection during mass production---In process quality control

Checking the goods after they are finished---- Final quality control

Checking the goods after they are finished-----Outgoing quality control

Packing and Delivery

Packaging of Cast Iron brake disc can be customized based on customer requirements to meet the different needs, such as plastic bag, carton box, wooden case, crate, etc.